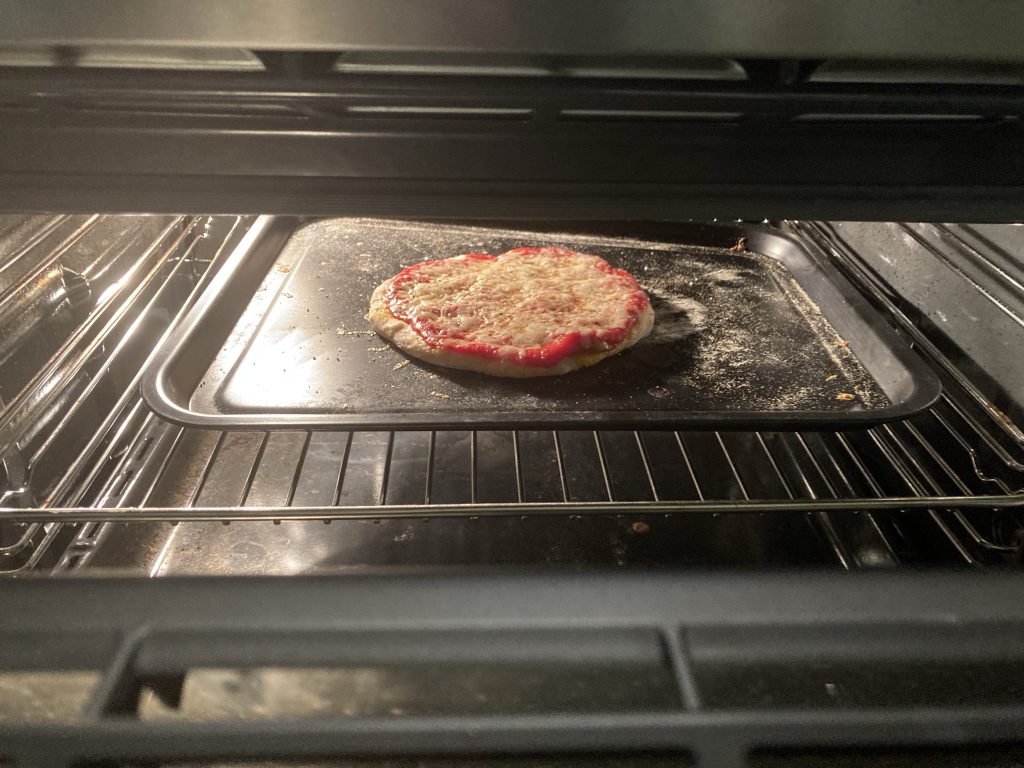

Oh, but when it rains, it doth pour, eh? Today our gas hob suddenly decided to start clicking constantly, which I suppose is a continual triggering of the ignition(s)?

Sometimes all four hobs were sparking continually, sometimes one or another. But the clicking was, more or less, constant, from around midday or lunchtime, till now (9pm)

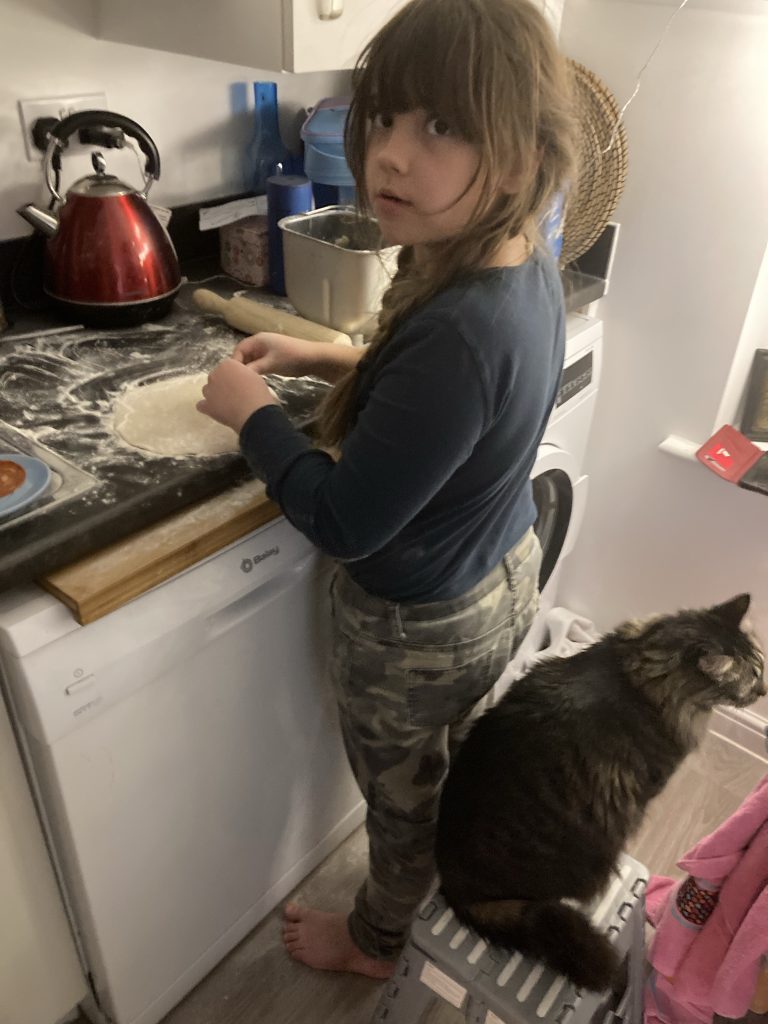

Of course I first tried solving it myself. This has happened once before. On that occasion I switched off everything (electric and gas*), and cleaned all the hobs. Cleaning can involve liquids, and liquids can short the spark circuitry! But I got everything as dry as I could. And, lo! Everything worked just fine.

* Or so I thought! Turns out I only knew how to switch the gas off for the hobs. The fuse on the main fuse board only switches off the oven and grill, not the hobs! More on this shortly.

Did the same this time, albeit ultimately spending much, much, much more time cleaning, but no dice. No change whatsoever! Clicking and firing continued unabated. Every now and again it’d lessen or stop. Only to start all over again.

Anyway, having gone back and forth, Googling the issue, and trying very hard to really clean out all the parts – the hobs comprise three components, plus the little (ceramic?) ignition ‘nipples’ – hoping it all might eventually dry out or summat, and stop firing, it was all to no avail.

I called a Gas Safe engineer at about 8.30pm. He arrived around 9.20pm. He determined we had no gas leaks. He also helped me identify the correct power socket for the hobs. I thought I’d done so. But apparently not. Whatever it was I’d found, it was the wrong power outlet!

Once the right power source had been identified, it became apparent that it did (the other lead/wall socket didn’t) have a switch. Mercifully, when this was flipped, the eternal and infernal clicking finally stopped.

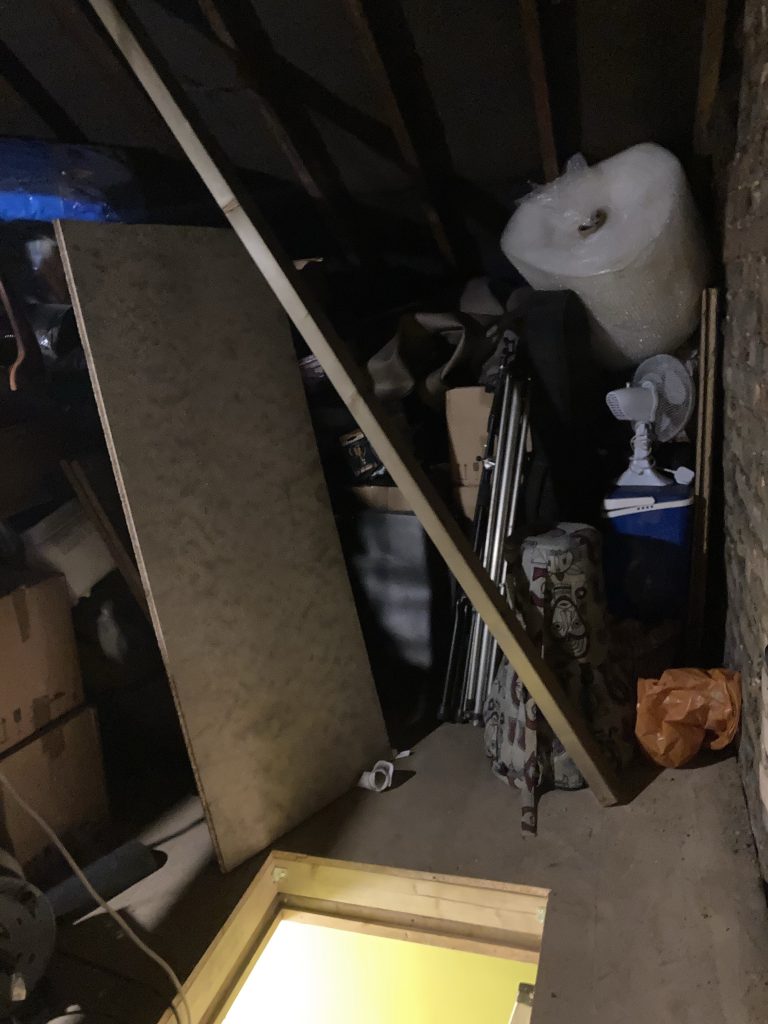

I have strong memories of recently packing away another four-hob cooker top. I think with a view to eventually installing it in our mooted Hobbit Hole guest accommodation? I tried to locate that today. But failed! We have way too much stuff, and way too little storage, so most of our stuff is in a cluttered state of disarray.

I wonder, should I find it, would it even fit?