Phew! What a bonkers day. I had another meltdown today. Outright panick is starting to kick in, occasionally. Not good!

A brief break from home and ‘my shit’ seems a basic medical necessity to me, right now. But our one night away, that we’ve been looking for’ard to for a while (to join in the celebrations of Teresa’s cousin’s wedding), Monday/Tuesday next week, has – like all our other forlorn attempts at holidays in the last four-plus years – fallen through. This time due to not having a road legal car available.

Quite aside from the crap that’s at the root of recent depressions, meltdowns and whatnot, the trip away issues are enough right now to send me über the edge. But sadly communications with my mum have been less than ideal for some time. And, on occasion recently, have gotten worse.

This last development, in a series of straws that have been conspiring to break this camel’s back, really knocked the stuffing out of me. And today that, and the failure to find a way to get to this wedding – plus everything else, frankly – just got to be too much.

So I had a bit of meltdown! Shouting, or rather screaming, as loud as I could, and hurling stuff around. Oh dear! In fact I’ve injured my right foot. Something I only realised much later, when having a bath: ‘Oh, right… that’s why my right foot has been feeling a bit odd all day!?’ I must’ve kicked something quite hard!

Perhaps my recent minor dalliance with Tears For Fears, via Scary Pockets sublime reworking of Everybody Wants A Gladstone Bag, has a deeper meaning for me? They were big into Papa Panov, or whatever his name was (Janov?), the Primal Scream dude. Hence Shout:

Well, having vented a bit, and despite all the shizzle not going away, Teresa and I got a fair amount done. We were originally due to be at Hannah’s today. Whilst we’ve loved and will miss looking after Ali and Sofi – Hannah starts a new job soon, with different hours – being at home this time was actually good from several perspectives, including the vantage point of just getting stuff done.

Utterly against my wishes, we’re preparing to let our spare room. Because needs must. It has functioned mostly as a dumping ground in recent years. Occasionally I’ve done some model-making type hobby stuff in there. But now we’re clearing it out, tarting it up. And, hopefully (!?)* we’ll be generating income with it soon.

* The irony here being that I really don’t to be sharing our home with strangers. But as already stated, needs must.

In order to blitz the guest or blue room clean – numerous previous attempts had failed! – I had to basically do a mega-dump (chortle!), out of it, and into any space nearby. Which meant dumping tons of stuff on the bed, in our bedroom. The blue room is still full of stuff that needs removing before we can think of letting it.

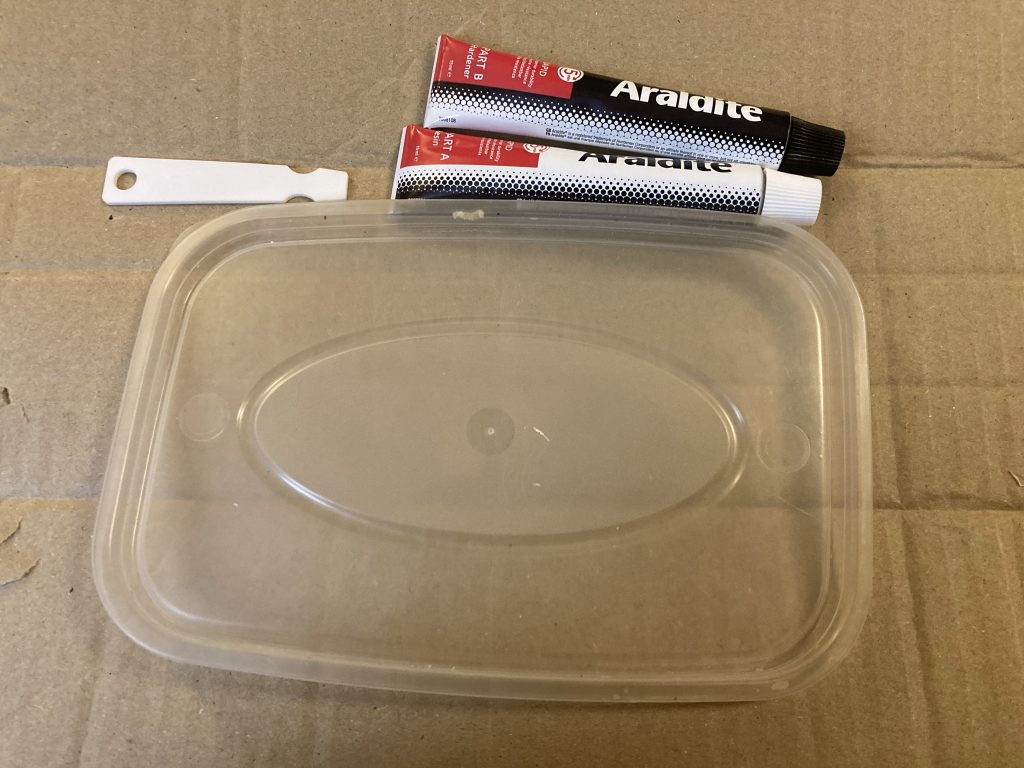

Anyway, we got a lot of stuff out of the blue room, and a good deal of that either up in’t loft, or elsewhere. A fairly large chunk of art related gubbins is migrating towards the ‘new’ art-studio.

This latter is in fact the old shed/workshop. And it’s humongously cluttered, and in flux, as stuff is moved out, in turn, to the newer bigger workshop.