Last Tuesday I managed to do a bunch of home and DIY stuff. In addition to what I’ve pictured here (very poorly, alas), in the loft, I also shifted some shelving units and 90% of our fairly big DVD collection, downstairs in the lounge.

I did the latter in order to shift the two sofas towards the back end of the house, and thereby allow the new mid-room partitioning curtains to hang better. Before one of them was getting hung up on ‘my’ sofa (the ultra tatty sofa-bed, which is now covered in a curtain throw).

Having done that, I then had to move masses of rather heavy boxes, full of books and magazines, etc, from one side of the loft to the other, in order to access the front. Once that was done – exhausting in itself – I could lay the beams and boards for an additional two runs of chipboard floor panels, as pictured below.

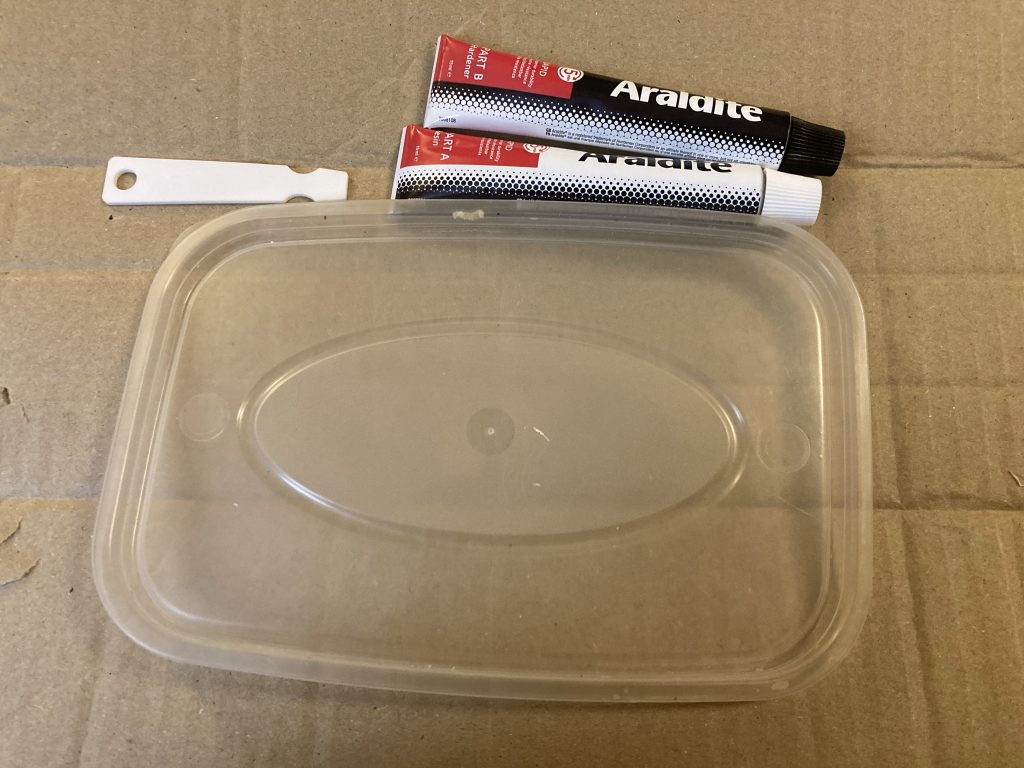

Two pics up is a short notched section of transverse beam. The beams that these beams rest on aren’t all level. The notches mean the boards should sit flat. I didn’t bother to do this on the very last beam. So there may be a bit of twisting in the final board.

The above photo, that shows the two boards in place, with square-ish gaps either end, is how I left things at days’ end. The nearer of the two new boards is screwed down. The farther one isn’t; I need to get the final piece of the the first one in place, before I can attach the final run of boards.

Hoping to get that done tomorrow!

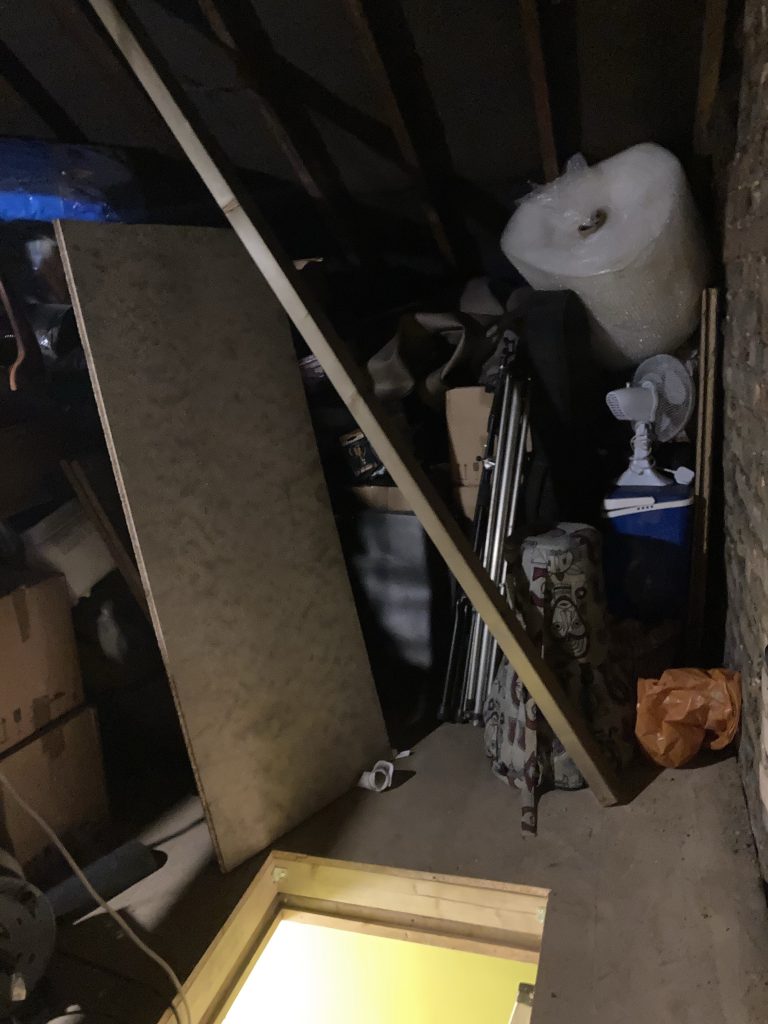

The final two pics show, albeit not very well/clearly, the sheer mounds of crap we have up in the attic. Once the flooring up there is complete I can start to actually rationalise and tidy all the stuff up there.

The large piece of timber that bisects the image below is the central horizontal roof tie-beam. If we want to make this attic space into a usable room, that’ll have to go!

Speaking of long wooden boards that had to go, I had to borrow a pry bar from Sean, at #72, to get a very rudimentary transverse beam (it had an unfinished outside-edge-of-the-log curved cross-section!) up and out of the way, in order the place the final transverse 2”x4” supporting beam.

Doing this kind of stuff up in our attic is filthy work. I had to wear gloves and a mask, due to all the dust, soot and dirt. This then plays havoc with my vision, fogging up my glasses. And on the topic of glasses, observant readers might spot a dram o’ whisky in one photo. Working man’s fuel, I guess?