I was scrolling through God knows what (FB, perhaps?), and somehow I went down a Lindy Beige / Nikolas Lloyd rabbit hole.

I read a bunch stuff about him, starting off with a thread that lead me to a Goodreads page, where someone called Nikolas Lloyd (and also an illustrator, named Christopher Steininger) are berated over the no-show of a kickstarter funded graphic-novel about Hannibal.

This was a bit alaruming, as I’d only ever known Lindy/Lloyd through his pretty affable YouTube content. I love the range of his interests, and – pretty much – his whole vibe, demeanour, schtick, call it what you will.

After reading a bunch of stuff by Lloyd, including most of the vegetarianism piece, I decided to email him, and share some responses/thoughts. Will he read it, or respond, I wonder?

Hi Nikolas,

I’m someone who occasionally enjoys watching your YouTube content.

I’m writing this email in response to reading about something that happened to you many moons ago, regarding a piece you wrote on Vegetarianism.

I’m not going to go into it all in the same way you do in that piece. I merely want to make a few points. And I would be interested in what you thought about them, should you have the time or inclination to respond.

I’ll try and keep this succinct.

Because you mention vegetarianism’s potential relationship with modern forms of Puritanism, I ought to mention that I was brought up in Christian circles.

My family drifted through many churches, over the years of my childhood, finally settling on a brand of watered down quasi American Evangelical type vibe. Quite fundamentalist: Biblical literalism (Creation, Flood, etc), speaking in tongues, and suchlike.

As soon as I was able to think coherently for myself, doubts about received religion set in. And by the age of something around 11-13, I had strayed from The Flock.

Ever since I’ve been an evolving form of what A C Grayling once described as something along the lines of a ‘rational humanist’ (I think his exact phrase may have been ‘free-thinking naturalist’, but I can’t find the quote).

Sorry if that seems a digression. But I hope you’ll agree, it’s contextualising and relevant.

Now to the meat of the matter, so to speak: I became vegetarian about aged 13. The cause? A documentary a class I was in at school watched about the fishing industry.

I’m no longer vegetarian, by the way. My vegetarian period lasted about 13 years. And ended when my then girlfriend (now wife) stopped conforming to to my veggie ways.

I read and enjoyed your piece, which – a bit confusingly to me (having got there via your ‘I was banned’ threads) – appeared to be titled with words you claimed not to have used (I’m thinking of your disavowal of Daily Mail inaccuracies), re forcing veggies to eat lard.

But never mind that. I’m in almost total agreement with you on all of the parts I actually read. I will confess I skim read several chunks.

I write and send this partly just to be in some kind of dialogue with a fellow thinker, with whom I share a lot of views/interests. But also partly to suggest that, as enjoyable as your piece on vegetarianism is/was, you don’t address – to my mind – the two chief and related reasons I always assumed (from both my own reasons for going veggie, and those of most vegans and veggies I’ve ever known and talked about the subject with) were the motivating factors: 1) animal suffering 2) industrialised practices.

When I ditched Christianity, I became a ‘friend’ of Buddhism. I’ve never been a Buddhist. But for about 15-20 years, I did meditation and yoga fairly regularly, as I found them useful for my mental and physical health. I also read quite a lot of Buddhist or Buddhist related/inspired literature.

One of their key arguments for vegetarianism is not causing suffering. And obviously killing other animals to eat them causes those animals suffering.

Of course, as you say, many animals are abundant through their relationships with humanity, from the mostly edible/wearable (sheep) to the mostly tractional/occasionally edible* (horses). But some of your stuff about how wonderful farmed animals have things, vs life and death in the wild, rang a bit hollow to me.

The human animal is a good example of one that we’ve thoroughly domesticated, but – ‘Civilisation & its Discontents’ – isn’t necessarily or always the better or happier for it.

As an example, from personal experience: I’ve been to former German concentration camps. And I went to the Spanish pig farm owned and run by my sister’s Spanish husband’s family. I watched piglets being castrated. The farm reminded me of the concentration camps. By then I’d resumed eating meat. What I witnessed made me think seriously about going back to my former veggie ways.

Of course many farmers do care for and even love their livestock. Even if only for economic reasons, such as you outline. But there is also an enormous amount of cruelty to animals, perhaps especially in the industrialised ways in which we ‘farm’ them nowadays.

It’s highly likely that a lot more people might decide to go veggie if they were to actually see the conditions many animals go through, between their birth and our guts. From the production line debeaking of chicks for battery farming, to the types of gases (and their effects) used prior to slaughter in abattoirs.

Now I’ll come back to that film I saw, as a young teen. The one that ‘turned me veggie’. It was a documentary, on modern fishing methods, largely focusing on the damage done to the environment, and the enormous wastage and cruelty of ‘bycatch’.

It being the open seas, it’s always been harder to police. But it was abundantly clear to me, a wet-behind the ear young teen, that some of the ways we were fishing then were both morally grotesque, and most likely totally unsustainable.

So, in a nutshell: animal suffering, and humanity’s endlessly repeated tendency to rapine exploitation of natural resources, are two strands I think you missed. And the two that, in my view, are perhaps most fundamental drivers towards the veggie way of life.

For all the reasons you eloquently relate in your article, and more, quite likely, I’m no longer vegetarian myself. But another way to look at my position might be… I’m lazy, uncaring, and I just can’t be bothered.

I don’t think deciding to be veggie can be or should be simply dismissed out of hand as miserabilist Puritanism, or no more than fashionable ‘virtue-signalling’.

For me it’s a complex and challenging issue, as are so many aspects of living life in the modern or current world.

Anyway, those are some of my thoughts on the subject.

With warm regards, Seb

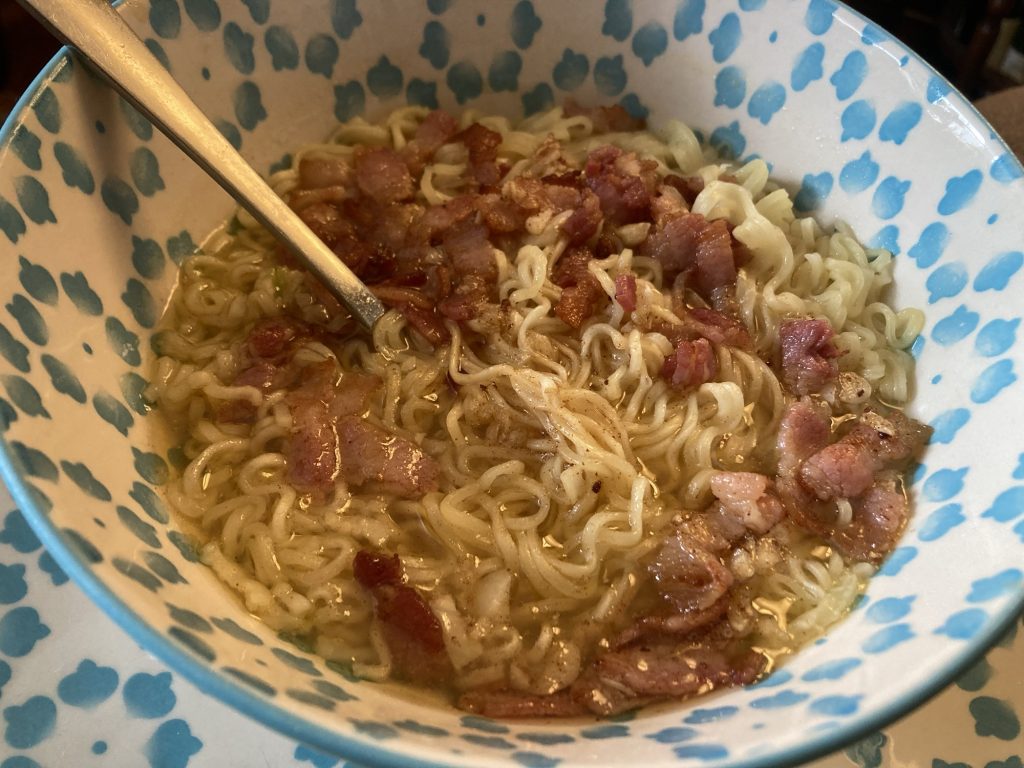

In other more domestic news… Teresa cooked Salmon with veg n’ spaghetti, for our supper. It was absolutely yummy! Thanks, sweetheart.