Yesterday I made all the basic parts for this plane, and then put them together. Today, I’m working on the central groove, the blade, and hopefully getting it to the stage of being a usable tool.

I tried cutting the ‘pyramid’ groove in the base of this plane with a router. But that was a disaster! Fortunately I did it – after numerous tests – in a shallow enough pass it didn’t entirely bugger the plane.

In the above two images you can see a bit of the residual damage the router attempt left, at right.

So, after attempting to tidy things up with chisels (a slight improvement), I came up with the right-angle sanding jig, shown below.

A massive improvement. But still far from perfect. And not the sharp, crisp 90° channel (at a 45° angle) I was after.

Having improved the groove, I tried setting the blade, or ‘iron’, and the wedge that holds it, in situ. After a few failed attempts (and much sanding of the iron, mostly trying to reduce the width a little, for a better fit), I finally got there.

A few attempts at using it established several things: 1) It does work as intended, albeit not very well (yet); 2) the blade ain’t sharp enough at present; 3) this is the biggest issues (after dullness o’ the blade) – there’s currently nowhere for chips or shavings to go, other than into the cramped/limited space where blade and wedge reside.

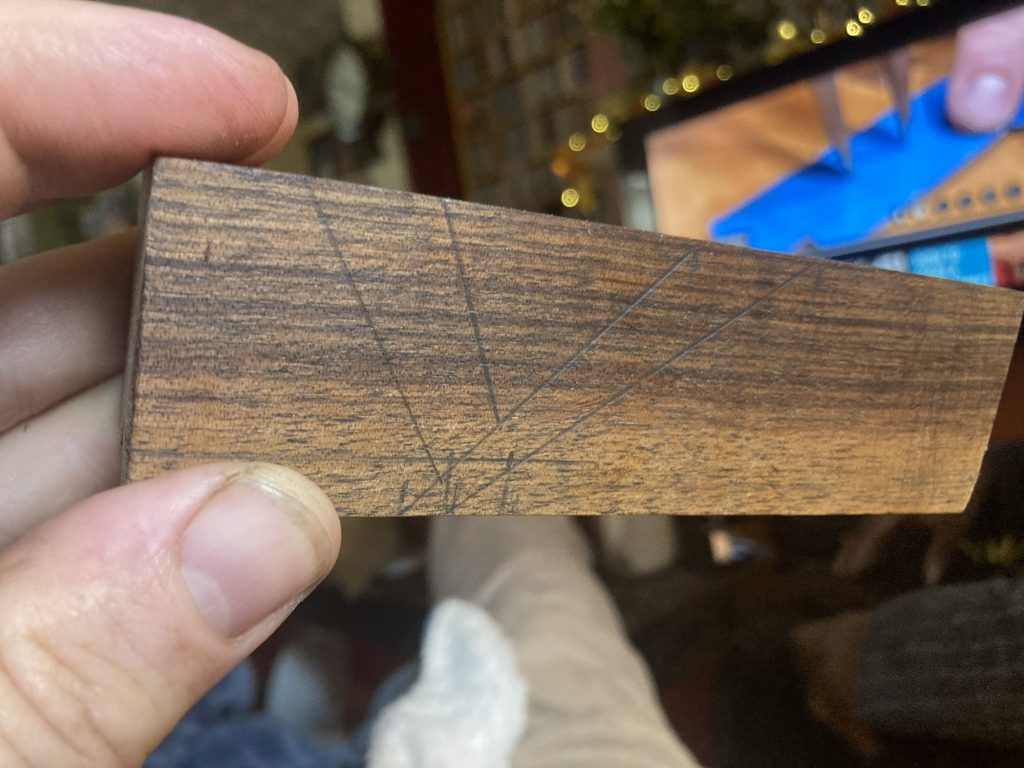

So, I’ve pencilled in a channel that needs drilling/cutting/chiselling, and otherwise hollowing out. Hopefully this will allow the chips or shavings/planing waste to exit, without clogging up the plane.

BUGGER BALLS!

Oh well… I’ve butchered this first plane attempt. In trying to chop out a chip/shaving channel, I completely jiggered the sole of the plane.

Some of the white oak tore out altogether. And a large-ish spilt in the walnut compounds the tragedy. Never mind! As depressing as I might find this outcome, the lesson I’m learning is to simply try again.

Some stuff I’ve been able to persist with, possibly even salvage. But not this time. And anyway, there were some design flaws inherent in this first attempt.

One of these issues was that the part that leads into the cut was too short; to better register as you move into the ‘cut’, a longer run up is good!

But the real issue was the omission altogether of a vent for chips and shavings. Lord knows I’ve watched enough Stavros Gakos videos I ought to have known better!

So… I’m gluing up some oak scraps, ready to try again. Plus I still have some walnut left. Although I might instead use keruing?