Am I getting back on track? Dare I hope so!?

My quest for a set of four screws (the originals removed and, it appears, lost!) to re-attach the base-plate of my Titan router ended in compromise. I found a set of four screws whose pitch wasn’t identical, but that fitted, albeit possibly damaging/reconfiguring the threads. Still, it allowed me to use the damned thing!

My neck support jig, and methods of clamping the neck, proved something of an issue. How clamp the neck so it won’t move and yet access it all for uniform depth routing? In the end this proved nigh on impossible. I did my best, and routed to a depth of c. 4mm, removing all the gouges and tear out.

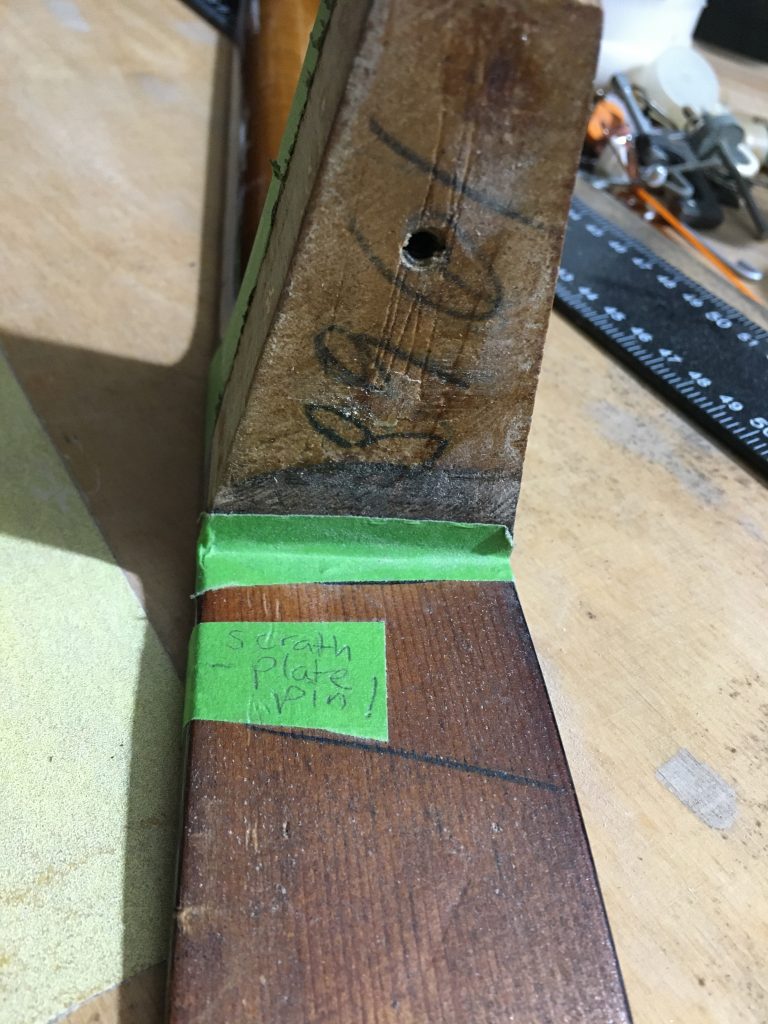

When routing with the jig supporting either side of the base-plate failed to produce the cleanly uniform surface I’d hoped for, I set up a flat sanding surface. As per the pictures. Hopefully this has some over the issues? It certainly looks nice n’ flat now.

All this work has revealed some interesting neck construction: the neck itself appears to be to piece, with a slightly odd kilter spline running, slightly wonkily, roughly down the lateral centre. This three part construction then joins to the heel, with a two-faceted joint. I’m the pic above one can see the junctions of these four parts. Note also a large-ish hole. what was this for? Fretboard positioning, perhaps?

At the headstock end of the neck are two more similarly sized hole. One is empty, the other filled with a wooden dowel. I used a knife – an ‘x-acto’ blade, as our American cousins might have it – to mark the top end of the neck, where the nut will sit.

I took the tuning pegs off. To facilitate the sanding of the neck. Due to the amount of material removed from the neck the sanding process has flattened a small area ‘biting’ into headstock territory. How this might affect the rebuild of the headstock – reattaching the plastic plate, etc . – remains to be seen.

In the photo above, a number I originally read as 1968 might actually be, read the other way up, 3961! What I took to be an eight can be seen at another point on the underside of where the neck projects over the arch top, below.

Some of this four digit number has disappeared, the neck length being shortened somewhat at this end by the removal of so much depth at a point where the neck tapered to a pretty thin area. But it’s pretty clear that the first digit is a 3, not an 8!

Thanks to Steve for drawing my attention to this!

Next I need to build back the list material somehow. Then I’ll need to rout out a channel for a truss rod. And for this I’ll need to establish neck length, or how long a truss rod (and fret-board) I need.

Got a busy drum-teaching day today. So I’ll either do this tonight, or over the weekend. Need to order the truss rod from Stew-Mac, State-side, so the sooner that’s done, the sooner I can progress this whole neck repair.